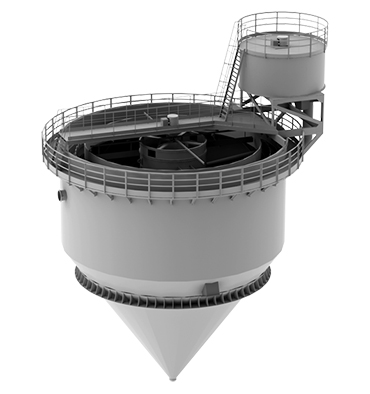

Flume water clarification tank

Flume water clarification tank ÒC-ÎÒÌ

It is designed for clarification of polluted water by mechanical suppression of polydisperse particles into mud. At the sugar factories it is used for beet top, roots, solid impurities and hovered particles of the ground removal out of flume water for reduction of water losses together with removed mud. Can be used together with the existing flume water clarification equipment in sugar, chemical and other branches of industry.

Structural features

Small area at the high productivity compared with traditional purification systems.

Adjusting of the mud suspension thickness.

There is a system of mud caking liquidation from the conical part of the tank.

Foam discharge from the system of water purification.

Possibility of mounting in the room that eliminates the dependence of work on the climatic conditions.

Quality

Water purification effect up to 70%.

Efficiency

Reduction of water consumption on run-around system feeding.

Reduction of electrical power consumption on water pumping.

Reduction of effluent discharge into canalization.

Decreasing of the load on the filtration fields.

Reliability

Unit operation during the whole production time without stops for preventative maintenance or repair.

Does not require highly skilled specialists.

Automation

The complex automation of the factory’s water-supply system is possible

Characteristics

|

Clarification tank productivity (at 10% soil (ground) content in the water): |

|

|

2 000 |

|

690 |

|

Moisture content in mud, % |

84-86 |

|

Mass, kg |

57 000 |

|

Overall dimensions – length, mm |

13 110 |

|

Overall dimensions – width, mm |

12 820 |

|

Overall dimensions – height, mm |

18 435 |