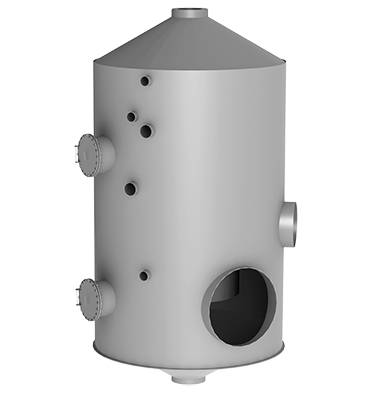

Massecuite vapour condenser of the A and B, C productsĺ vacuum pans

Massecuite vapour condenser of the A and B, C products’ vacuum pans TC-KUP

It is designed to condense the vapour from the vacuum pans and secondary vapour from the final evaporating stage of the evaporation plant, formation of the required desaturation to assure set temperature mode of the products boiling in the sugar industry. It can be also used for distilling, separating and for other plants of the food industry.

Structural features

There is developed fluidic-cascade system of water distribution.

Low sensitivity to the possible scale deposits at the surfaces of water distribution system.

Simple construction is designed to work with high vacuum.

Low hydraulic resistance.

Possibility to operate in a wide range of vapour consumption.

Simple mounting (does not require clamping device).

Possibility of an additional complement with a remote separator for water separation from the non-condensed gases.

Vapour condensation in three stages: I stage (fluidic) – for water heating on diffuser feeding, II stage (cascade-fluidic) -principal condensation, III stage (cascade-fluidic) – condensation of the vapour residuals non-condensed at the II stage and cooling of the non-condensed gases.

Massecuite vapour condenser of the B and C products’ vacuum pans (operational principle analogical to the described above) which differs by overall dimensions and by the absence of stage designed for water heating on diffuser feeding.

Quality

Optimization of the massecuite boiling process and consumptions of the heating vapour for this goal through the possibility to make a vacuum set by the technological mode.

Wide range of the vapour and water consumption.

Efficiency

Minimal difference between the temperature of heated (spent) water and the vapour supplied to the condensation, accordingly minimal possible consumptions of the water.

Minimal expenses on water pumping.

Decreasing of the loading on the vacuum-air pumps due to cooling of the non-condensed gases till the optimal temperature.

Maximal possible heating of the water for the feed of diffusion plants.

Possibility to work using only circulating water in condition if there is no necessity in technical water use for diffusion units feeding.

Reduction of fuel consumption on technological needs due to the optimization of the massecuite boiling process.

Increasing of the condenser working efficiency through the use in the scheme of vacuum-condensate unit the raw juice heater on the massecuite vapour.

Reliability

Stable work during the whole production time, even in case of scale deposit on the condensate surfaces.

Stability of the vacuum at the changeable modes of plant’s work and unstable quality of the processed raw materials.

Characteristics

|

Steam consumption, t/h |

45 |

|

Hydraulic resistance, Pa |

≤ 50 |

|

Vacuum in condenser, kg/cm2 |

0,85 |

|

Mass, kg |

1 200 |

|

Interior diameter, mm |

3 400 |

|

Overall dimensions – length, mm |

3 841 |

|

Overall dimensions- width, mm |

3 690 |

|

Overall dimensions – height, mm |

6 768 |