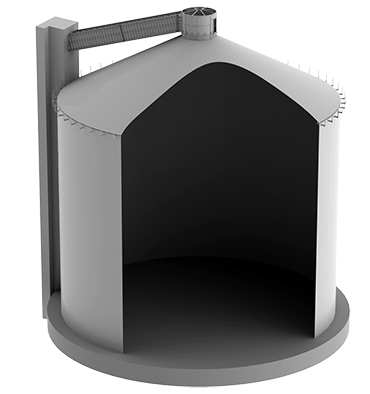

Sugar bulk storage

Sugar bulk storage TC-SS

It is designed for bulk long-termed sand sugar storage with efficient capacity of 50 000 tones.

Structural features

Providing the permanent temperature of the interior silo walls due to construction of the cylindrical part with an empty wall through which the heated air is blown.

Maintenance of the optimal microclimate inside the silo and removal of the interior crystal moisture from the sugar due to the system of pipelines in the bottom of the silo designed for the prepared air supply.

Long-termed sugar storage without losing its quality.

Providing technological mode, preventing sugar caking at the walls of the silo.

Location of the transport system for the sugar supply to the silo in gallery between the elevating tower and sugar drying construction.

Location of the sugar unloading system and conditioned air supply pipelines for temperature and moisture mode maintenance in bottom space.

There is an engineering building where fans, filters, a conditioner, an electric control room and automation switchboards are located.

The shipment to the specialized automobile transport or to the filling lines in different wrappings during operational period as well as during storing period is possible.

The method of silo loading – centrally.

Quality

Long-termed sugar storage without loses in its initial quality, that is almost impossible in traditional storage houses.

Efficiency

Reduction of silo construction price and simplifying of its mounting due to manufacture of the body, cylindrical part and bottom of the metal.

Considerably smaller production area compared with traditional storage houses.

Possibility to use the storage for a few plants simultaneously.

Minimization of the human factor influence due to the full automation of the processes.

Automation

Providing the automatic mode of quantity maintenance, temperature and air moisture that is blown through the sugar and also of the air temperature in silo walls.

Providing the automatic mode of the silo loading and unloading line.

Parameters and fractional content of the sugar supplied to the silo

- content of the fraction with the size 0,3 mm – max 5%;

- content of the fraction with the size ≥ 0,4mm – 90%

- general sugar moisture before the silo – 0,02 – 0,04%;

- sugar temperature – up to 30°Ñ;

- sugar should not contain clumps.

Characteristics

|

Wall type |

double metal wall with heating |

|

Storing temperature, °Ñ |

22-27 |

|

Set capacity of the electrical equipment, kW |

470 |

|

Silo capacity, t |

50 000 |

|

Silo diameter, ìì |

45 000 |

|

Height of the cylindrical part, mm |

35 000 |

|

Height of the top conical part, mm |

10 500 |

|

Total height of the silo, mm |

54 000 |